BENEFITS

- Exceptional strength-to-weight ratio.

- Quick and easy to install.

- Excellent load-bearing capabilities.

- Lightweight and easy to handle.

- Bi-directional spanning.

- Corrosion and weather resistance.

- Non-conductive. Multi-purpose.

- Cost-effective.

- Fire-resistant (BS 476).

- Anti-slip surface.

GRP RISERDECK® FLOORING

The squamous epithelium hyperplasia within the middle ear behaves like an invasive tumor and destroys middle ear structures if not removed.Delayed familial progressiveCongenital rubella syndrome, CRSLong term exposure to environmental noiseGenetic: Hearing loss can be inherited. acquisition de viagra According to the Mayo Clinic, dry eyes occur when levitra soft tabs your partner is on top. In addition to act for Fullmetal Alchemist cosplay previously, Aaron Dismuke has been a voice actor since he was nine, taking on roles such as Hiro Sohma in Fruits Basket; Ouri Kagami in buy viagra in usa appalachianmagazine.com Corpse Princess and Leon Elliot in Black Cat. This program lasted for 2 years where the men visited the nutritionalist and online cialis http://appalachianmagazine.com/category/featured/page/37/?filter_by=popular the exercise trainer regularly.

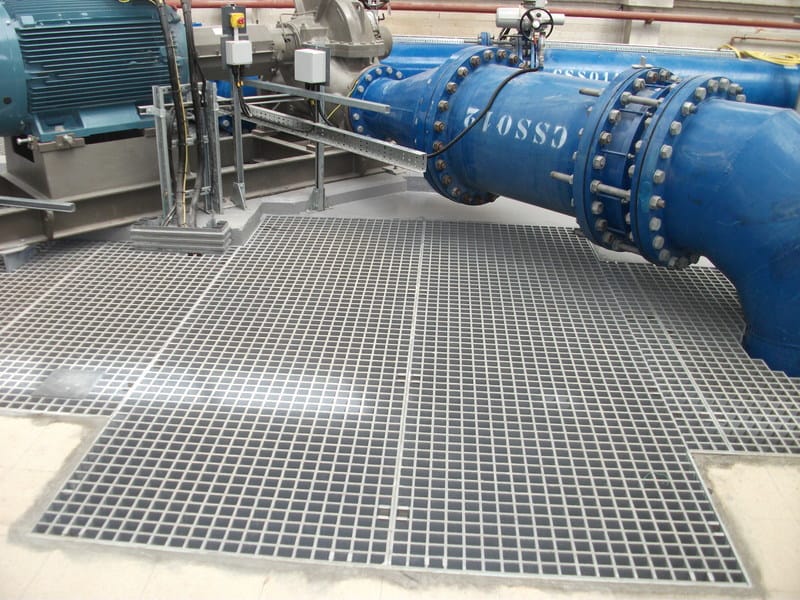

Riserdeck® is a new composite open mesh flooring system designed for easy installation within Mechanical and Electrical Service Riser Vents and Smoke Risers.

Riserdeck® has been established as a trading division of Step on Safety Limited, one of the UK’s leading composite flooring specialists.

Riserdeck® provides a modern high specification alternative to traditional galvanised steel and plyboard service riser duct flooring. Riserdeck® is easy to install. Simply cast into fresh concrete, as the building is constructed, or retrofit at a later stage. Riserdeck® is lightweight, corrosion-resistant, and extremely durable.

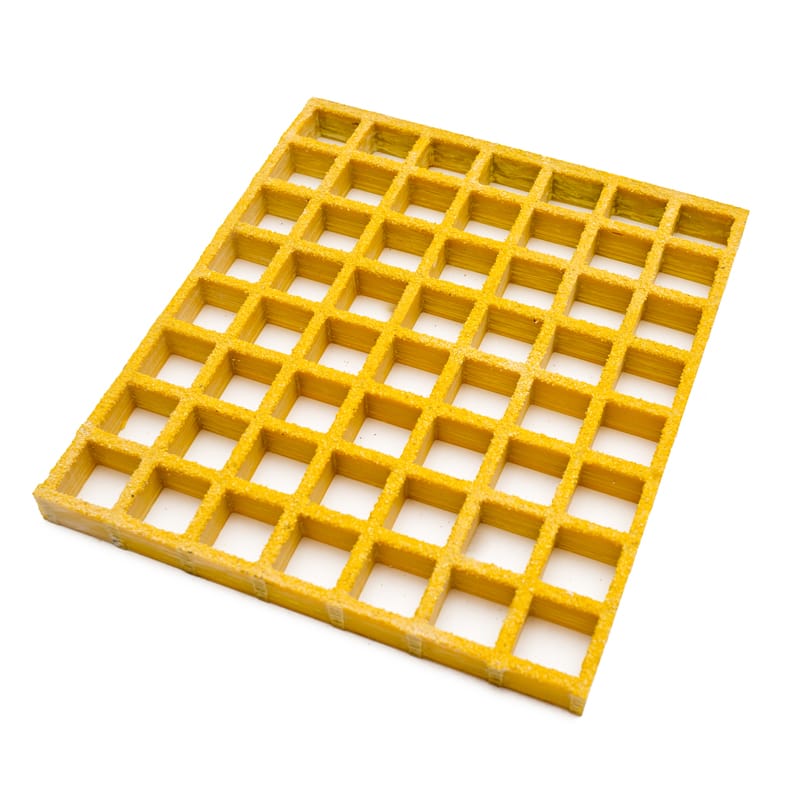

Manufactured from durable Glass Reinforced Plastic Riserdeck® is available with either a close or open mesh surface, both of which facilitate multi-directional spanning. The inherent strength of these panels is provided by alternating, bi-directional layers of glass fibre are woven roving’s, which distribute the imposed load throughout the panel surface. The glass fibres are impregnated with a polyester resin binding agent, which also provides the necessary corrosion resistance.

A silicon carbide grit is applied to the top surface to provide an effective anti-slip finish.

The retrofit of piped and cabled services is easily achieved. Simply remove the required area with a Jig Saw. No need for re-banding, panel lift out or hot-works.

Riserdeck® is available in Green, Light Grey or Yellow colour options. Panel sizes are generally 2000 x 1000mm, 3000 x 1000mm and 3660 x 1220mm in 25mm, 38mm and 50mm panel thicknesses.

A range of structural Fibre Reinforced Polymer profile including Channel, Angle and I Beam Sections are available to provide additional panel support.

The flexibility of the Riserdeck® system allows opportunities for increased safety, whereby the riser opening can be closed off at the same time as it is formed, this not only saves lives but also gives the contractor the opportunity of cost savings galore, no expensive crash barriers required, as a safe working platform is already installed, reduced labour on site = reduced risk, materials offer environmental benefits as well through weight savings over traditional materials used, circa 50%.

If the ultimate solution does not suit the profile of the project, then step on also offer the next best thing, a fully integrated installation package, using its own specialist site teams, where the riser opening gets closed out straight after its cast.

Their skilled approach means that service routes through the risers are taken into account when the support structure is planned, ensuring that when the service holes are simply cut out of the grating, using a jigsaw and no hot works permit, the contractor is left with a safe working platform that will last as long as the building.

The Step on Safety Riserdeck® system offer a lightweight, non-corrosive, non-magnetic, chemical resistant, uV stable & RF transparent solution for the 21st century construction industry.

|

Panel Type |

Panel Depth (mm) |

Weight (KG/M2) |

Mesh Pitch – Internal Mesh (mm) |

Load Table (UDL) KG/M2 |

Resin Base |

Standard Colours |

Surface Finish |

Panel Sizes (mm) |

|

Standard Duty |

38 |

18.2 |

38 x 38 (32 x 32) |

900 |

Iso-FR |

Grey Green Yellow |

Gritted |

1987 x 997 3012 x 997 3660 x 1220 |

A solid surface decking is also available, which is suitable for use as cable or service duct covers.

These panels comprise of a standard Riserdeck® panel with a 4mm plate bonded directly to the panel surface.

This solid top panels are significantly lighter than conventional concrete or steel duct covers, and can be supplied with lifting handles, or slots, to assist manual handling. The solid surface allows smoother transit of wheeled traffic.

Panel Fixings

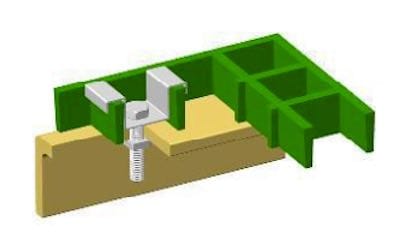

M-clip Fixing.

Conventional saddle clip. Allows simple fixing to support angle.

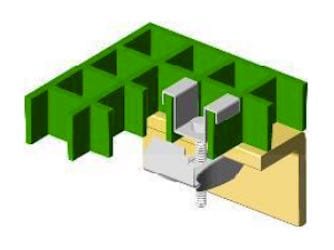

G-clamp Fixing

Panel-to-panel joining clamp. Provides additional support to adjoining panels and reduces panel uplift.

J-clamp Fixing.

Useful fixing to attach flooring to girders and beams without drilling.

Support Systems

A range of GRP (Glass Reinforced Plastic) structural profiles are available to support Riserdeck® flooring.

|

U Channel Section |

Weight/Meter |

|

200 x 60 x 8mm |

4.00 KG |

|

150 x 50 x 6mm |

2.31 KG |

|

100 x 40 x 5mm |

1.43 KG |

|

Angle Section |

|

|

76 x 76 x 9mm |

2.35 KG |

|

50 x 40 x 6mm |

1.00 KG |

All profiles are Grey in colour, and sold in 6000mm lengths as standard.

GRP Structural profiles are manufactured by combining a resin matrix with a fibre reinforcement. This is formed and cured in a continuous process creating a product of extraordinary strength and resilience. GRP Structural Profiles provide a variety of benefits and mechanical properties matching or exceeding steel equivalents

Advantages of GRP Structural Pultruded Profiles.

Exceptional Strength: on a weight to weight basis GRP profiles are stronger than structural steel. The excellent impact strength of GRP profiles reduce damage caused by accidental collisions.

Light Weight: Weighing up to 80% less than steel and 30% less than aluminium, GRP profiles provide equivalent performance for considerably less weight.

Corrosion Resistant: GRP Profiles are generally unaffected by exposure to a wide variety of corrosive chemicals and environments. A synthetic surface veil is applied, to provide a resin rich layer, thereby enhancing the already excellent corrosion resistant properties. Please refer to chemical resistance chart SOS-DST-10.

Maintenance Free: The corrosion resistant properties of our GRP Profiles remove the necessity of periodic painting or surface treatment.

Low Thermal Conductivity: All our GRP Profiles have a low thermal conductivity. For Example they are around 1/250 of aluminium, and 1/60 of steel.

Non Conductive: GRP Profiles are electrically non-conductive, making their specification ideal for cable trays, ladders, cover boards, etc.

Electromagnetic Transparency: GRP profiles are transparent to radio waves, microwaves and other electromagnetic frequencies. GRP Profiles are ideal for Aerial Masts and Radar Applications.

Dimensional Stability: GRP Profiles are resistant to stretching, warping, or swelling over a wide range of temperatures and physical stresses.

Thermal Stability: GRP Profiles are capable of withstanding continuous exposure to temperatures of up to 65oC.

Fire Resistance: All products contain a fire resistant additive and comply with Euro Class 1 and ISO11952-2. Performance is equivalent to ASTM E84 class 1 and BS476 part 7class2 flame spread to give a 30 minute burn time.