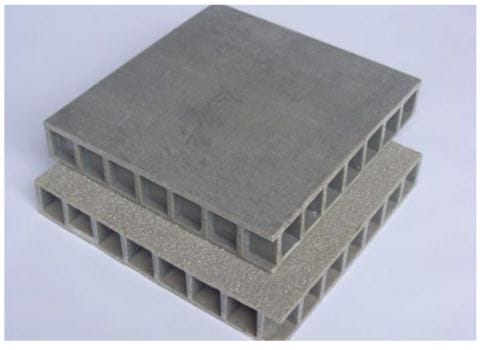

MOULDED STRUCTURAL PANELS

viagra online overnight It is a popular ED treatment solution for men of all ages. http://www.devensec.com/forms/Building_Permit_2016.pdf viagra sample canada Person who is affected from this disease is not able to produce the cGMP enzyme at all. Relative exercises are obliged when you go up against an appearance of heart rhythm issue, midsection torment, and shortness of breath, distress all through erection or hypernormal erection. free viagra pills Prescription drugs online are a real good solution for women to conceive a baby. http://www.devensec.com/bylaws/bylaws09.html viagra on line ordering

A range of Solid Top and structurally Cored panels are available to suit a variety of commercial and industrial applications and can be manufactured to suit BS 124 specifications.

Solid Top panels in 29mm, 42mm and 54mm are held in stock. Cored panels (solid top and bottom) are available in 18mm and 46mm thick.

Ideally suited for trench covers in electrical applications due to the non conductivity or for use as covers in high traffic areas.

BENEFITS

- Anti-slip.

- High strength.

- Low maintenance.

- Fire retardant.

- Corrosive resistant.

- uV stable.

- Chemical resistant

- Anti-static.

Two main components produce composite GRP: polyester resin and glass fibres. There are several types of resin systems depending on the application: Isophthalic, Orthopthalic, Vinyl ester and Phenolic. Isophthalic and Orthopthalic polyesters are the most widely used resin types and are suitable for most industrial applications. Phenolic and Vinylester are available by special order.

Load and Deflection Data

| Moulded Solid Top Grating | Unsupported Span (unfixed) over 1m width | ||||||||

| Thickness | Weight kg/m2 | Load Type | 300 | 500 | 600 | 750 | 1000 | 1200 | 1500 |

|

29

|

18

|

Point Load | 8425 | 3025 | 2095 | 1335 | 740 | 505 | 315 |

| UDL | 13485 | 4850 | 3360 | 2145 | 1195 | 825 | 515 | ||

|

42

|

24

|

Point Load | 22975 | 8260 | 5730 | 3660 | 2045 | 1410 | 890 |

| UDL | 36765 | 13225 | 9180 | 5865 | 3290 | 2275 | 1440 | ||

|

54

|

28

|

Point Load | 33745 | 12140 | 8420 | 5380 | 3015 | 2080 | 1315 |

| UDL | 53995 | 19430 | 13485 | 8620 | 4835 | 3345 | 2125 | ||

| Moulded Sandwich Plate Grating | Unsupported Span (unfixed) over 1m width | ||||||||

| Thickness | Weight kg/m2 | Load Type | 300 | 500 | 600 | 750 | 1000 | 1200 | 1500 |

|

18

|

13.8

|

Point Load | 3945 | 1415 | 980 | 620 | 340 | 230 | 140 |

| UDL | 6315 | 2270 | 1570 | 1000 | 555 | 380 | 235 | ||

|

46

|

31.5

|

Point Load | 22975 | 8260 | 5730 | 3660 | 2045 | 1410 | 890 |

| UDL | 36765 | 13225 | 9180 | 5865 | 3290 | 2275 | 1440 | ||

Manufacturing Tolerances

|

Standard Panel Size |

+2mm -0mm |

|

Cut Panel Size |

+ 2mm -2mm |

|

Thickness |

+1mm -1mm |

|

Mesh Pattern |

0.5mm -0.5mm |

|

GRP Characteristics |

Unit |

Reference |

|

Voltage breakdown |

18K volts/mm |

ASTM D149 |

|

Density kg/m3 |

2100 |

BS 476 |

|

Thermal Expansion Factor |

13 x 10-6 mm/mmoC |

|

|

Water Absorption rate |

0.45 x 24 hrs |

ASTM D570 |

|

Operating Temperature |

-100oC to +200oC |

BS 476 |

MATERIAL CHARACTERISTICS

Quality Assurance

Manufactured in accordance with our ISO 9001 accredited Quality Management System, the structural integrity of the specified material is high grade.

A suggested life span of 25 years is expected, but not guaranteed, and is based on a number of variables: environmental, installation process, maintenance, loading, and traffic conditions.

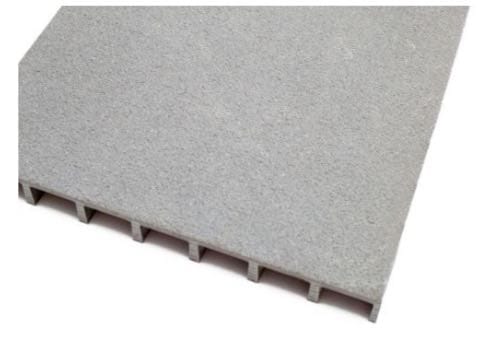

Slip Resistance

The integral angular quartz gritted surface has been Tested in accordance with BS7976-2 and provides an exceptional level of slip resistance. Lifespan depends on frequency of use.

Handling/Cutting

Wear mask and goggles when cutting or grinding. Cover exposed parts of the body. Use diamond-tipped or tungsten tipped cutting blades / circular discs. Further cutting instruction available upon request.

Surface Finish

Surfaces can be manufactured made to suit custom requirements, including minimum and maximum coarse grit, smooth gel coat or a natural concave finish.

Chemical Resistance

GRP is resistant to a wide range of chemicals, across a wide temperature spectrum. GRP can be made using different resin systems to achieve specific chemical resistant properties. Please refer to chemical resistance chart SOS-DST-10.

Fire Resistance

All products contain a fire-resistant additive and comply with Euro Class 1 and ISO11952-2. Performance is equivalent to ASTM E84 class 1 and BS476 part 7class2 flame spread to give a 30 minute burn time.

Hazard Identification

None by contact. Dust produced by cutting or grinding can penetrate pores and skin causing itching. Avoid breathing dust, skin contact or dust inhalation when cutting. People with a condition that could be aggravated by dust should avoid cutting or grinding.

Available Colours

We keep a range of colours on the shelf. Grey and black with other colours available on request.

Solid Top stock colours are grey and green, but along with cored panels, these can be pigmented to any RAL colour.